Important user information

This manual explains how to install, operate and configure a GCP-MG. This device may only be used for the applications described in this document.

This manual is to be used with a GCP-MG with firmware version 1.0 to 1.5.

These instructions are intended for use by trained specialists in electrical installation and control and automation engineering, who are familiar with the applicable national standards and safety procedures.

Safety Precautions

|

|

ELECTRICAL HAZARD

Failure to follow these instructions could result in death or serious injury! |

Document conventions

Throughout this manual we use the following symbols and typefaces to make you aware of safety or other important considerations:

|

|

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. |

|

|

Indicates a potentially hazardous situation that, if not avoided, could result in damage to equipment. |

|

|

Indicates information that is critical for successful application and understanding of the product. |

|

|

Provides other helpful user information that does not fall in above categories. |

|

|

Provides supplemental user information. |

|

Acronym

|

This typeface is used to introduce acronyms or product names. |

Command

|

This typeface is used to represent commands, prompts, input fields and filenames. In the context of programming it is used for functions, variable names, constants or class names. |

Placeholder

|

This typeface is used to represent replacable text. Replaceable text is a placeholder for data you have to provide, like filenames or command line arguments. |

User input

|

This typeface is used to represent data entered by the user or buttons. |

Screen output |

Screen output or program listing |

Introduction

The GCP-MG is a next-generation Modbus/CAN gateway specifically designed to interface Woodward’s GCP-30 Series Genset Controls and LS 4 Circuit Breaker Controls with Modbus networks.

The GCP-MG gateway has been developed in cooperation with Woodward to ensure the highest possible degree of interoperability with Woodward equipment.

The gateway features CAN, serial RS-232 and RS-485 ports as well as an Ethernet port and can be mounted on a DIN rail. On the CAN side it implements the Woodward CAL protocol to connect to the GCP controls. On the serial ports and on Ethernet it implements a Modbus server (Modbus RTU and Modbus/TCP) and accepts connections from Modbus master devices like PLCs and SCADA systems.

Usage and configuration of the gateway is simple and conveniently performed using a web browser which connects to the embedded web server.

Possible areas of application are:

-

PLC connection

-

Operator panel interfacing

-

HMIs

-

SCADA integration

-

Power station automation

-

Gen set control

-

Remote control & monitoring

-

Data logging

Features

The GCP-MG gateway provides the following key features:

-

Modbus/TCP protocol (Ethernet)

-

Modbus RTU protocol (either RS-232 or RS-485, software configurable)

-

Interfaces with up to 16 GCP-30 controls and up to 8 LS 4 controls

-

Full support of Option SB03 (Cat CCM) and Option SC06 (MTU MDEC)

-

Modbus register layout compatible with GW 4

-

Dedicated Modbus slave ID for each GCP-30 and LS 4 control

-

Large internal buffer for data

-

Complete data set of one GCP-30 unit can be read with a single Modbus transaction

-

Integer/Exponent value pairs for voltages, power and currents are additionally represented as 32-bit floating point registers

-

Transparent handling of data guarantees compatibility with future Woodward firmware updates

-

Serial baud rate up to 115200 bps

-

Support of Modbus function codes 03, 04, 06 and 16

-

Concurrently one Modbus serial line and up to two Modbus/TCP connections

-

Low configuration overhead, just an IP address

-

Embedded web server for easy configuration and commissioning using a web browser

-

Firmware upgradeable via Ethernet

-

Status LEDs for power, Ethernet link, device status and communication status

-

24 V DC (10-30 V) power supply

-

DIN rail mountable

Quick start checklist

-

Read this set of instructions properly and in its entirety.

-

Mount the unit.

-

Connect the power. Do not connect yet CAN bus or serial ports.

-

Configure the Ethernet communications settings with a web browser (using an Ethernet crossover cable) or with a terminal program like HyperTerminal (using a null modem cable)

-

Configure the CAN bus settings.

-

Configure the serial line communication settings.

-

Configure the operational aspects of the device.

-

Wire CAN bus.

-

Wire serial line interfaces.

Description

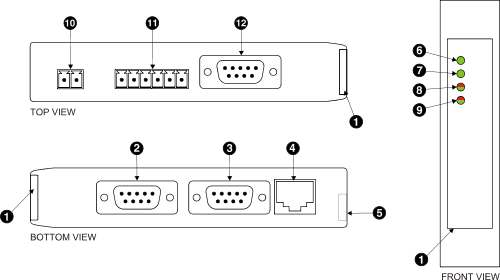

The power, CAN and RS-485 terminals are placed on the top side of the unit. The RS-232 and Ethernet connectors are placed on the bottom side of the unit as shown in the following illustration:

LED indicators

Four LEDs located at the front panel indicate the status of the GCP-MG. The LEDs assist maintenance personnel in quickly identifying wiring or communication errors.

A LED test is exercised at power-up, cycling each LED off, green and then red for approximately 0.25 seconds. At the same time the power-on self test of the device is performed.

The following table outlines the indicator condition and the corresponding status after the power-on self-test has been completed:

| LED | Function | Condition | Indication |

|---|---|---|---|

Power |

Power |

Off |

No power applied to the device. |

Green |

Power supply OK |

||

Link |

Ethernet link |

Off |

No Ethernet link |

Green |

Ethernet link OK |

||

Status1 |

Device status |

Off |

The device has an unrecoverable fault; may need replacing. |

Flashing green |

Device operational but needs commissioning due to configuration missing, incomplete or incorrect. |

||

Green |

The device is operating in normal condition. |

||

Flashing red |

Device operational but has a fault listed which requires acknowledgment. |

||

Red |

The device has an unrecoverable fault; may need replacing. Flashing sequence and rate of Status2 LED indicates fault class. |

||

Status2 |

Communication status |

Off |

CAN connection OK, Connection time-out on Modbus |

Green |

Both Modbus and CAN connection OK |

||

Flashing red-green |

Modbus connection OK, Connection time-out on CAN |

||

Flashing red |

Connection time-out on both CAN and Modbus |

||

Red |

The device has detected an error that has rendered it incapable of communicating on CAN. |

Principles of operation

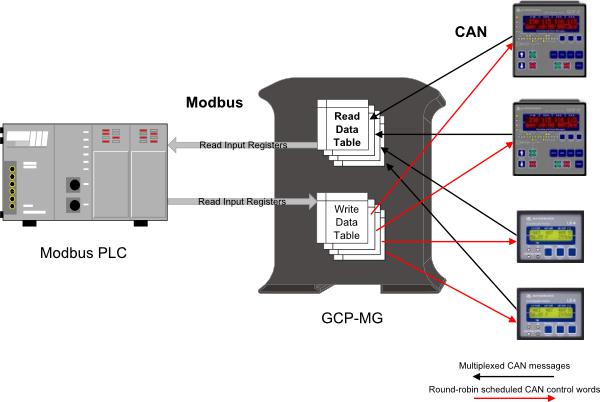

The GCP-MG establishes a communication channel to each GCP-30 and LS 4 unit connected to the CAN bus. All GCP-30 and LS 4 units transmit multiplexed data values which the GCP-MG stores in its internal data tables. A GCP-30 for example sends a new value every 100 ms, a LS 4 every 200 ms.

The GCP-MG acts as a Modbus server on Ethernet and the serial interface. It accepts connections and Modbus queries from Modbus master devices. The Modbus registers are then served from the GCP-MG's internal data tables. Because of the data table buffering, the Modbus can be polled significantly faster than the update rate on the CAN bus. However faster poll rates would not offer higher update cycles of the data values. The GCP-MG allows a maximum of 2 connections via Modbus/TCP and in addition one serial connection via either RS-485 or RS-232.

For remote control, a Modbus master writes control words to a dedicated internal data table which is then cyclically sent to the corresponding GCP-30 or LS 4 unit. One remote control data table is processed every 100 ms. This makes the remote control update cycles depend on the number of units enabled for remote control. For example if 3 GCP-30s are enabled for remote control, it takes 300 ms to send all control words to all GCP-30s, if all 16 GCP-30 and all 8 LS 4 units are enabled for remote control it takes 2.4 seconds ((16 + 8) x 0.1 s) to transmit all control words to the connected units.

Installation

Regulatory notes

|

|

|

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

This Class A digital apparatus complies with Canadian ICES-003.

Unpacking, handling and storage

|

|

|

Before connecting anything

|

|

|

DIN rail mounting and removal

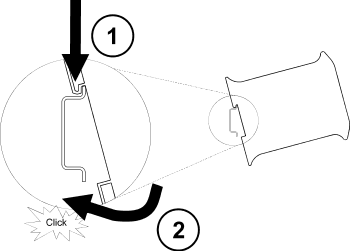

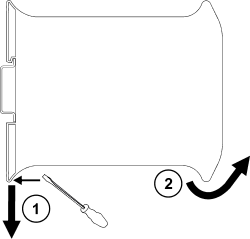

The GCP-MG gateway is designed to be mounted on a 35 mm DIN rail according to DIN/EN 50022. The enclosure features a 35 mm profile at the back which snaps into the DIN rail. No tools are required for mounting. Please observe the rules outlined in [Mounting].

|

To mount the unit on a DIN rail, slot the top part of the GCP-MG into the upper guide of the rail and lower the enclosure until the bottom of the red hook clicks into place. |

|

To remove the GCP-MG from the DIN rail, use a screw driver as a lever by inserting it in the small slot of the red hook and push the red hook downwards. Then remove the unit from the rail by raising the bottom front edge of the enclosure. |

Mounting rules

The enclosure provides protection against solid objects according to IP 20 / NEMA Type 1 protection rating. When mounting the unit observe the following rules:

|

|

|

Powering the GCP-MG

|

|

Before connecting power please follow the rules in [Safety] and [Connecting]. |

Power is supplied via a 3.81 mm 2-pin pluggable terminal block located at the top side of the mounted unit (refer to [DescriptionDiagram]). The following table and picture shows the power terminal socket pinout:

|

|

|

|

Make sure that the polarity of the supply voltage is correct before connecting any device to the serial and CAN ports! A wrong polarity can cause high currents on the ground plane between the V- power supply pin and the CAN port and serial port ground pins, which can cause damage to the device. |

Wiring the CAN interface

The CAN interface connects to the GCP-30 and LS 4 devices.

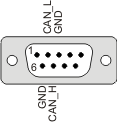

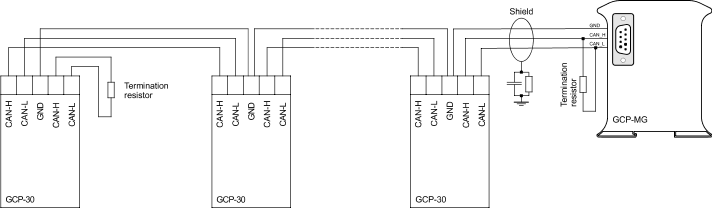

The CAN connector is a male 9-pin D-sub type located at the top side of the mounted unit (refer to [DescriptionDiagram]). It has industry standard CiA DS-102 pinout as shown in the following table and picture:

|

|

-

The network must be terminated at both ends with its characteristic impedance, typically a 120 Ohm 1/4 W resistor.

-

Maximum number of electrically connected CAN nodes is 64

[The number of logically adressable units may be less.]

. -

Maximum CAN cable length is 250 m (820 ft) and is derated depending on bit rates and cable type.

-

Stub connections off the main line should be avoided if possible or at least be kept as short as possible. Stub connections must not have terminating resistors.

-

To ensure a high degree of electromagnetic compatibility and surge protection the cable should be twisted pairs and shielded. An additional cable conductor or pair may be used for the CAN_GND reference.

|

|

Do not connect the cable shield to the CAN_GND pins or the connector shell! Use an external chassis ground connection to terminate the shield. |

The following diagram illustrates a typical interconnection between GCP-30 units and the GCP-MG:

Wiring the RS-485 Modbus interface

The RS-485 Modbus interface is used for integrating the GCP-MG into a two-wire Modbus over Serial Line network. The use of the RS-485 interface must be configured using the web interface (See [ModbusConfig]). The GCP-MG is a Modbus slave device.

The RS-485 signals are located at the 3.81 mm 6-pin pluggable terminal block on the top side of the mounted unit (refer to [DescriptionDiagram]). The following table and picture shows the pinout:

RS-485 |

|

-

Line termination is required and is typically done with a 120 Ohm 1/4 W resistor. For RS-485 operation the bus must be terminated at both ends.

-

Maximum number of RS-485 nodes without repeater is 32.

-

Stub connections off the main line should be avoided if possible or at least be kept as short as possible. Stub connections must not have terminating resistors.

-

Maximum cable length to 1200 m (4000 ft).

-

To assure a high degree of electromagnetic compatibility and surge protection the cable should be twisted pairs and shielded. An additional cable conductor or pair may be used for the GND reference.

|

|

Do not connect the cable shield to the GND pins! Use an external chassis ground connection to terminate the shield. |

Wiring the RS-232 Modbus interface

The RS-232 Modbus interface can alternativly be used for serial communication to a Modbus master device instead of RS-485. The use of the RS-232 interface must be configured using the web interface (See [ModbusConfig]). The GCP-MG is a Modbus slave device.

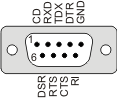

The RS-232 Modbus connector is a male 9-pin D-sub type located at the bottom side of the mounted unit (refer to [DescriptionDiagram]). It has industry standard EIA-574 data terminal equipment (DTE) pinout as shown in the following table and picture:

|

|

-

Maximum cable length is 15 m (50 ft) or a length equal to a line capacitance of 2500 pF, both at the maximum standard bit rate of 20 kbps. If operating at higher bit rates the maximum cable length drops to 3 m (10 ft) at a bit rate of 57.6 kbps.

-

To assure a high degree of electromagnetic compatibility and surge protection the RS-232 cable should shielded. The shield shall be connected to an external chassis ground at the either or both ends, depending on the application.

-

The shield must not be connected to the GND pin.

|

|

To connect the GCP-MG to a PC (Personal Computer) or any other device with data terminal equipment (DTE) pinout you need a null-modem or cross-over cable. |

Connecting Ethernet

The following table describes the 10BASE-T Ethernet RJ-45 connector pinout:

|

|

-

We recommend to use Category 5 UTP network cable.

-

Maximum cable length is 100 m (3000 ft).

Connecting to the diagnostic port

The device’s second RS-232 interface is used as a diagnostic port and only active after power-up of the device. It allows configuration of the IP settings and reset of the settings to factory defaults via a terminal program.

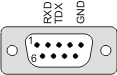

The Diagnostic port connector is a male 9-pin D-sub type located at the bottom side of the mounted unit. It has industry standard EIA-574 data terminal equipment (DTE) pinout as shown in the following table and picture:

|

|

-

Maximum cable length is 15 m (50 ft) or a length equal to a line capacitance of 2500 pF, both at the maximum standard bit rate of 20 kbps. If operating at higher bit rates the maximum cable length drops to 3 m (10 ft) at a bit rate of 57.6 kbps.

-

To assure a high degree of electromagnetic compatibility and surge protection the RS-232 cable should shielded. The shield shall be connected to an external chassis ground at the either or both ends, depending on the application.

-

The shield must not be connected to the GND pin.

|

|

To connect the GCP-MG to a PC (Personal Computer) or any other device with data terminal equipment (DTE) pinout you need a null-modem or cross-over cable. |

Ethernet & IP configuration

Before configuring the GCP-MG, obtain a unique static IP address, subnet mask, and default gateway address from your network administrator.

The factory default IP address of the GCP-MG is 169.254.0.10 which is in the Automatic Private IP Addressing (APIPA) address range.

There are several methods of configuring the unit’s IP address:

-

Removing your PC from your corporate network and using a cross-over network cable (see [ConfigCrossOver]).

-

Via the diagnostic port and a terminal program like HyperTerminal (see [ConfigTerminal]).

-

Leaving your PC connected to your corporate network and temporarily changing the IP settings on your PC to match the subnet of the GCP-MG (see [ConfigChangeIP]).

|

|

In order to connect to the GCP-MG via TCP/IP, your PC must be on same IP subnet as the gateway. In most situations this means that the first three numbers of the IP address have to be identical. |

IP setup using a web browser and a cross-over network cable

This method applies only to operating systems like Windows, which support APIPA (Automatic Private IP Addressing). It also requires your PC to be configured for DHCP. If your computer is configured with a static IP address, follow the procedure in [ConfigChangeIP].

-

Disconnect your PC from your corporate network. If your computer is configured for DHCP it should now automatically fall back to use a default IP address from the APIPA range 169.254.x.x (Windows PCs only).

-

Connect an Ethernet crossover cable from the GCP-MG to the computer.

-

Start Internet Explorer.

-

In the address box, type

169.254.0.10and then pressEnter. -

Click

Configuration…and thenEthernet & IPin the menu on the left side of the page. -

Enter the IP address, subnet mask, and gateway address assigned to your GCP-MG, then click

Save. -

Reconnect your computer to your corporate network.

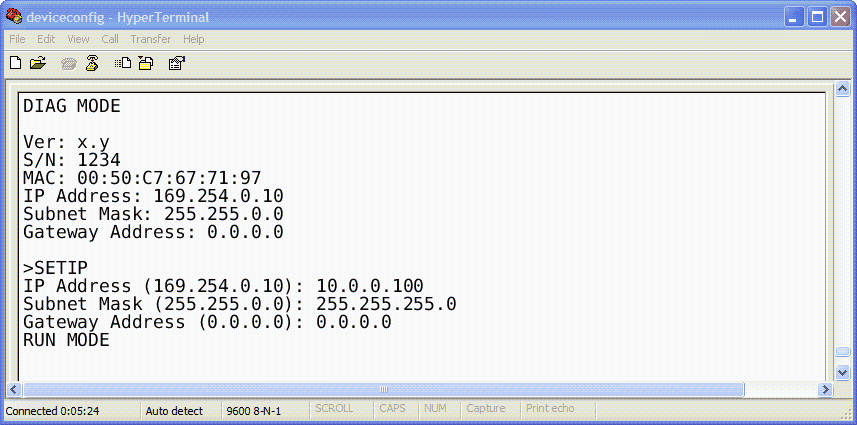

IP setup using a terminal program like HyperTerminal

-

Connect a null modem RS-232 cable between your PC and the GCP-MG's diagnostic port.

-

In Windows XP, click

Start, point toAll Programs, point toAccessories, point toCommunications, and then clickHyperTerminal. -

When HyperTerminal starts, it opens a dialog box and asks for a name for the new connection. Enter a name (for example,

deviceconfig) then clickOK. -

The

Connect todialog opens. Select the COM port you will be using in theConnect usingdrop-down list box, then clickOK. -

Select

9600,8,None,1,Nonein theCOM Propertiesdialog, then clickOK. -

HyperTerminal is now connected to the serial line.

-

Keep the

spacebar pressed in HyperTerminal and power-cycle your device at the same time. -

A menu should appear after one or two seconds showing device information, the current IP configuration and a

>prompt. -

Type

SETIP, then pressEnterwithin 10 seconds after the prompt is shown:

-

The device will show current values and prompt for new values for IP address, net mask and gateway address. Enter the new values and press

Enter. A key press must be received at least every 10 seconds otherwise the device will go back to RUN MODE and resume normal operation. -

The gateway will return to the main prompt. Type

Xand pressEnterto leave DIAG MODE and resume normal operation indicated withRUN MODE.

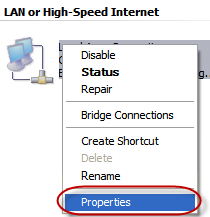

Temporarily changing the IP settings on your PC

This method involves manually assigning an IP address to your PC in the same subnet as the gateway. The default subnet of the gateway is 169.254.0.0/16.

-

Connect the GCP-MG to your Ethernet network.

-

On a Windows PC, open the

Control Paneland double-click onNetwork Connections. Right-click on the Network Connection associated with your network adapter and selectProperties:

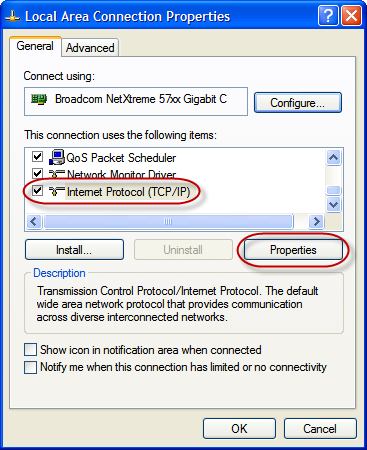

This will show the

Local Area Connection PropertiesDialog:

-

Select the

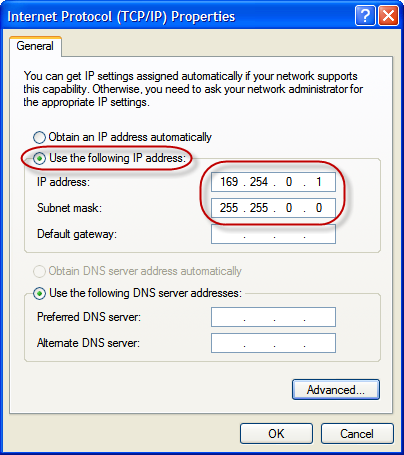

Internet Protocol (TCP/IP)entry and click onPropertiesto open the TCP/IP Properties dialog as shown below:

-

Write down your current settings so they can be restored later.

-

Select

Use the following IP addressand configure a static IP address in the same subnet as the device, for example169.254.0.1and the subnet mask255.255.0.0. ClickOKto save the changes. -

Start Internet Explorer.

-

In the address box, type

169.254.0.10and then pressEnter. -

Click

Configuration…and thenEthernet & IPin the menu on the left side of the page. -

Enter the IP address, subnet mask, and gateway address assigned to your GCP-MG, then click

Save. -

Restore your computer’s original settings.

Web browser based management

The GCP-MG incorporates an embedded web server. This allows you to connect to the device and monitor and configure it using a web browser. Most browsers should work, provided they support JavaScript. We recommend Internet Explorer 6.0 or higher.

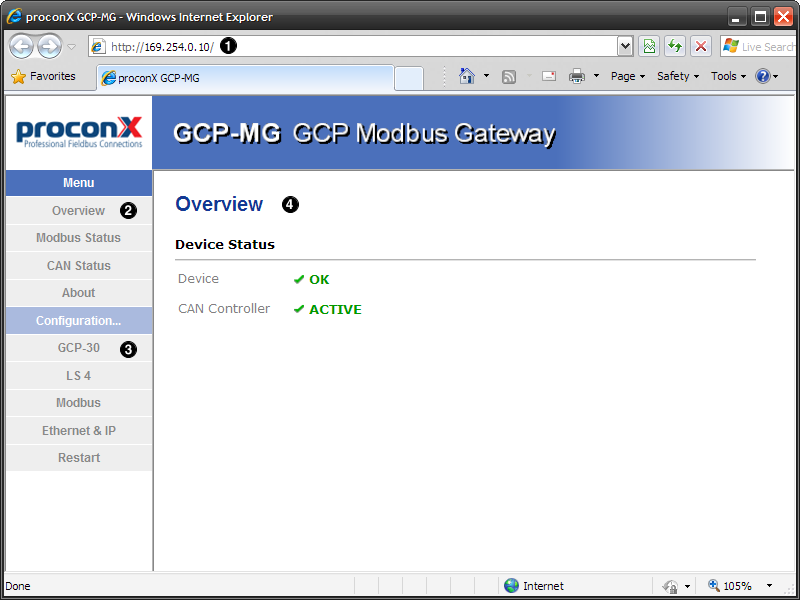

Connecting to the GCP-MG

Once you made sure that your PC is configured to be on the same subnet as

the GCP-MG, start your web browser. In the address box, type the IP

address of your device (169.254.0.10 is the default), and then press

Enter. (See [EthernetConfig])

The web browser will establish communication with the embedded web server and an overview page similar to the following picture will appear:

Use the menu bar shown on the left side to navigate the different pages.

|

|

In order to connect to the GCP-MG via TCP/IP, your PC must be on same IP subnet as the gateway. In most situations this means that the first three numbers of the IP address have to be identical. |

Monitoring and diagnostic

The GCP-MG offers several web pages which allow monitoring of the status of the different communication networks and the device performance.

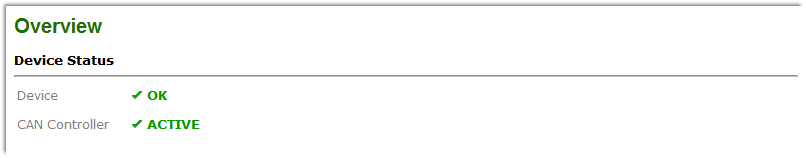

Device status

The Overview page shows the principal device status as shown in the

following picture:

The value shown in the Device row represents the device status register

which keeps track of run-time faults. All run-time faults are latched and

must be reset by the user. The following faults can be listed here:

-

OK -

The device is fault free.

-

Watchdog reset -

This warning indicates that the device was reset by it’s internal watchdog supervision circuit.

-

Brown out reset -

This warning indicates that the device was reset by it’s internal supply voltage monitoring circuit. This fault occurs when the supply voltage drops below the lower limit.

-

Device out of memory -

This warning indicates that the internal dynamic memory has been exhausted and due to this a certain function could not be completed.

-

Device configuration data write failure -

This alarm indicates that the configuration data could not be written to the non-volatile memory. Configuration data changes will be lost once the device is power-cycled or reset.

-

Reset to factory defaults -

This alarm indicates that the device' configuration data was reset to factory defaults. The device requires re-commissioning.

The CAN controller status indicates the status of the CAN interface and

can be in one of the following states:

-

ACTIVE -

The CAN bus is fault free.

-

PASSIVE -

CAN’s built in fault confinement mechanism has set the node to error passive state due to a large number of errors on the CAN bus. This warning indicates a wiring error.

-

BUS-OFF -

CAN’s built in fault confinement mechanism has set the node to bus-off state due to excessive errors on the CAN bus. This alarm indicates a wiring error. The GCP-MG will not transmit or receive any message on the CAN bus once entered this state. The device needs to be manually restarted on order to recover from this fault.

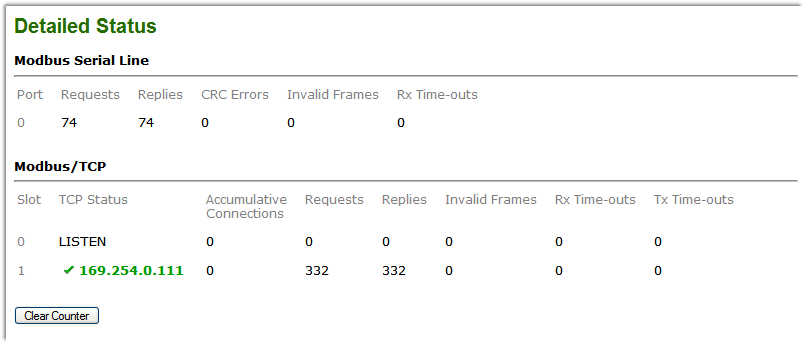

Modbus connection status

The Modbus Status page shows status and statistics about the Modbus

traffic. These values provide valuable information used to troubleshoot

Modbus network problems. This page is automatically updated every

5 seconds.

|

|

This page shows accumulated readings since the GCP-MG was last activated or reset. If power to the GCP-MG is lost, all cumulative values are reset to zero. |

The following statistics are maintained:

-

TCP status -

Status of the TCP/IP connection as per TCP finite state machine (refer to RFC 793). If no client is connected the status indicates

LISTEN. If a client is connected, it’s IP address is shown. -

Accumulative connections -

A counter that increments each time a client opens a Modbus/TCP connection.

-

Requests -

A counter that increments each time an inbound request message is successfully received.

-

Replies -

A counter that is incremented each time a reply message is sent back to the master. This includes exception replies.

-

CRC errors -

A counter that increments each time a message is received that has a CRC that does not match what is calculated. Typically the result of wiring issues. Messages with CRC errors are discarded and not replied to.

-

Invalid frames -

A counter that increments each time a malformed Modbus frame is detected. Malformed frames are for example messages larger than the allowed maximum PDU size defined in the Modbus standards. This can be caused by non-Modbus traffic on the network.

-

Rx time-outs(Modbus serial line) -

A counter that increments each time an inter-character time-out occurred during the reception of an inbound message.

-

Rx time-outs(Modbus/TCP) -

A counter that increments if the master connection has timed out. Subsequently the connection is terminated by the GCP-MG. A time-out occurs if no Modbus request is received from a connected client within a 10 second period.

-

Tx time-outs -

Number time-outs occurred when attempting to send a reply message.

The cumulative diagnostic data is reset when the device is power cycled or

reset. The data is also reset by pressing the Clear Counter button.

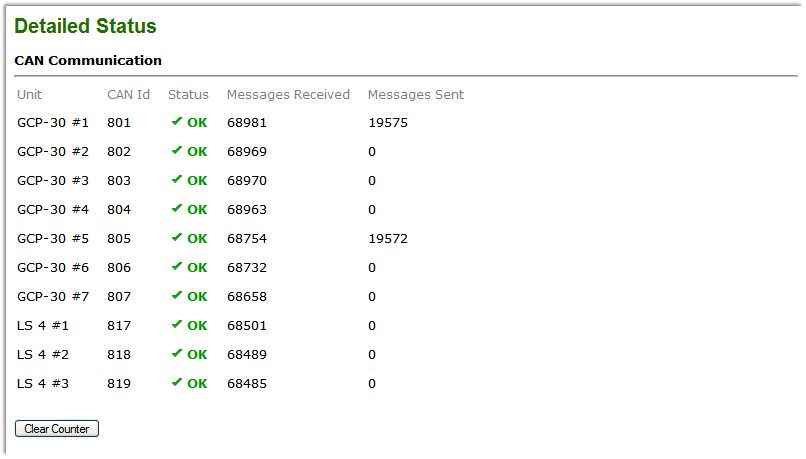

CAN communication status

The CAN Status page shows status and statistics about the CAN bus traffic.

These values provide valuable information used to troubleshoot CAN

problems. This page is automatically updated every 5 seconds.

|

|

This page shows accumulated readings since the GCP-MG was last activated or reset. If power to the GCP-MG is lost, all cumulative values are reset to zero. |

The CAN communication channel between a GCP-30 or LS 4 unit and the GCP-MG can be in one of the following states:

-

OK -

The CAN communication channel with the GCP-30 or LS 4 unit has been established. The GCP-30 or LS 4 control is cyclically updating data.

-

WAIT -

The presence of a GCP-30 or LS 4 unit has been detected however the GCP-MG is currently waiting to receive a complete data set. It takes approximately between 2.3 and 3 seconds to receive a full data set from the GCP-30 and approximately 10 seconds from the LS 4.

-

TIME-OUT -

No CAN message was received for a period of 1 second. A GCP-30 control is supposed to send a CAN message every 100 ms, a LS 4 every 200 ms.

The following statistics are maintained:

-

Messages received -

A counter that increments each time an inbound CAN message matching the shown CAN ID is successfully received.

-

Messages sent -

A counter that is incremented each time a CAN message is sent. CAN messages are only sent if Remote Control is enabled for this GCP-30 or LS 4.

The cumulative diagnostic data is reset when the device is power cycled or

reset. The data is also reset by pressing the Clear Counter button.

Finding the firmware version and serial number

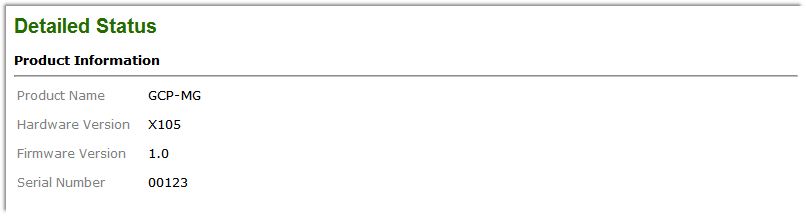

Click on the About menu entry on the menu bar to show

the product information as shown below:

This product information is important for service and support inquiries. The following product information is provided:

-

Product name -

The name of the product.

-

Hardware version -

GCP-MG hardware version.

-

Firmware version -

The firmware version that is installed on the GCP-MG.

-

Serial number -

The serial number of the GCP-MG. The serial number is specific to your device.

Configuring and commissioning

The configuration pages are accessed by clicking on the Configuration…

menu entry on the menu bar which then expands a configuration sub-menu.

All configuration settings are kept in the device' non-volatile memory.

|

|

If you make changes to any settings, remember to save each page before changing to a different page! |

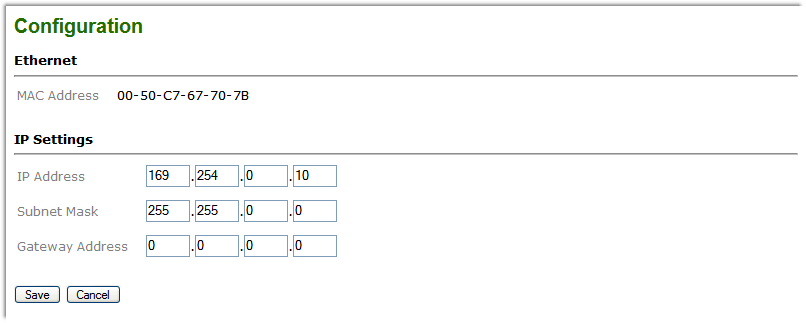

Configuring Ethernet and IP

Select the Configuration→Ethernet & IP sub-menu from the menu bar to open

the Ethernet and IP settings which are shown below:

The following Ethernet parameters are shown:

-

MAC address -

The device' unique MAC address. This number is hard coded and cannot be changed.

The following Internet protocol (IP) settings can be entered:

-

IP address -

The IP address assigned to this device.

-

Subnet mask(also known as network mask) -

If you have a router, enter the subnet mask for the segment to which this device is attached.

-

Gateway address -

If your network segment has a router, enter its IP address here. Otherwise leave the address as

0.0.0.0.

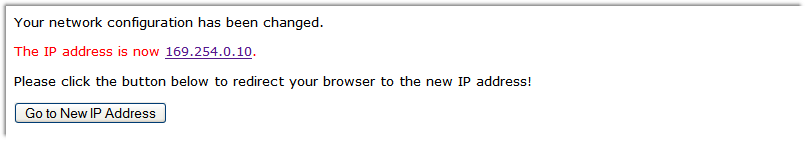

Once you click Save the new settings are stored and applied instantly.

The new settings are confirmed with the following page:

|

|

Please write down the new IP address so you are able to communicate with the device in the future! |

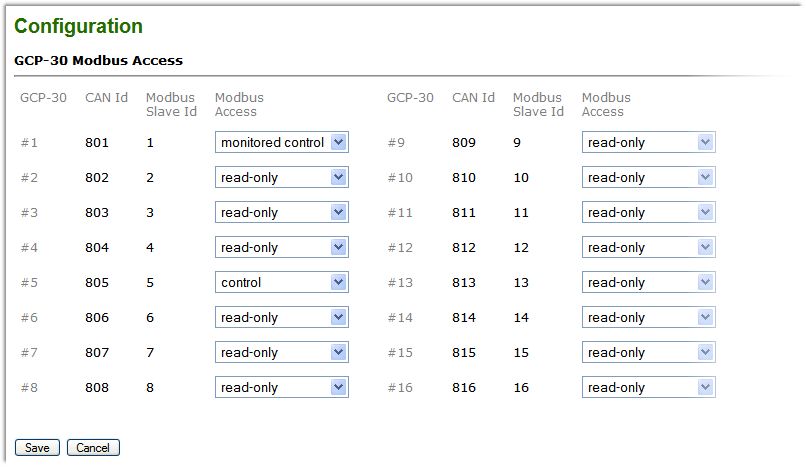

Configuring GCP-30 and LS 4 Modbus access

Access from the Modbus to a GCP-30 and LS 4 unit can be configured on a per unit basis. You have the option of completely disabling a gen set control for Modbus access, have read-only access or enabling remote control either unsupervised or time-out supervised.

To configure the Modbus access, enter the Configuration sub-menu and click

on either the GCP-30 or LS 4 menu entry. This opens either the

GCP-30 settings or the LS 4 settings as shown below:

The CAN identifiers and Modbus slave identifiers are preassigned and cannot be changed. The following Modbus access options can be selected:

-

disabled -

Modbus access to this unit is completely disabled. The gateway does not respond to a Modbus master query and ignores messages for the associated Modbus slave ID. The associated slave ID can be used by another Modbus device connected to the Modbus network.

-

read-only -

Modbus access is enabled for read-only data. No remote control is possible, access to the remote control data table 4:0001 will result in Modbus exception code 03 Illegal Value being returned.

-

control -

Modbus access is enabled for reading and for remote control. No supervision of Modbus master activity takes place (See Monitored Control). Before being able to use Remote Control, please check that the GCP-30 unit has been parameterized accordingly, otherwise the messages sent by the GCP-MG are ignored by the GCP-30. Refer to chapter Interface in your GCP-30 Series Genset Control manual. For Remote Control to work, GCP-30 parameter 120

Control via COM X1X5must be turned on and discrete inputAutomatic 2(Terminal 5) must be asserted. If remote alarm acknowledgment is required, GCP-30 parameter 122Ackn. F2,F3 via COM interfmust be turned on in addition. If power setpoint shall be accepted by the GCP-30, discrete inputAutomatic 1(Terminal 3) must be de-energized and parameter 78Power set point value: external inputmust be set toOFF. -

monitored control -

Similar to

controlbut in addition the remote control is monitored and a Modbus muster must cyclically update the remote control words by writing to the remote control data table. If a Modbus master fails to do this within a certain time limit, the GCP-MG will trigger anInterface error X1X5alarm on the GCP-30. For Monitored Control to be effective, GCP-30 Parameter 121Supervision X1X5must be turned on.

Once you click Save the new settings are stored and applied instantly.

A confirmation message is shown.

|

|

It is of great importance to ensure that there is not two devices with the same Modbus address. In such a case, an abnormal behavior of the whole serial bus can occur, the master being then in the impossibility to communicate with all present slaves on the bus. |

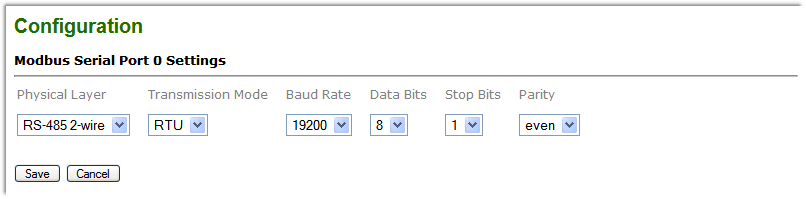

Configuring serial line Modbus

The Modbus settings for serial line can be configured to match the network

configuration of your Modbus master device. Select the

Configuration→Modbus sub-menu from the menu bar to open the Modbus

settings which are shown below:

The following Modbus settings can be entered:

-

Physical layer -

Can be set to two-wire

RS-485orRS-232mode. RS-485 is the default. Depending on this setting either the D-sub (RS-232) connector or the terminal block connector (RS-485) of the GCP-MG is utilized. -

Transmission mode -

Only RTU mode can be selected here.

-

Baud rate -

9600 and 19200 are the most common baud rates for Modbus. 19200 is the default setting.

-

Data bits -

Only 8 data bits can be selected here which is a requirement for RTU.

-

Stop bits -

Can be configured to be 1 or 2. The Modbus standard mandates that 2 stop bits are configured when using no parity.

-

Parity -

Changes parity mode to either none, even or odd. The default parity mode for Modbus is even parity.

Once you click Save the new settings are stored and applied instantly. A

confirmation message is shown.

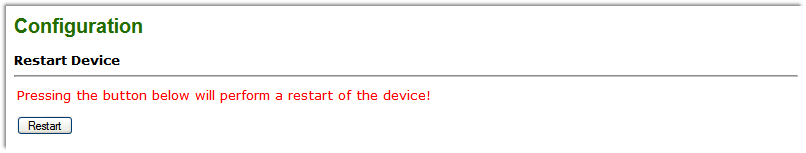

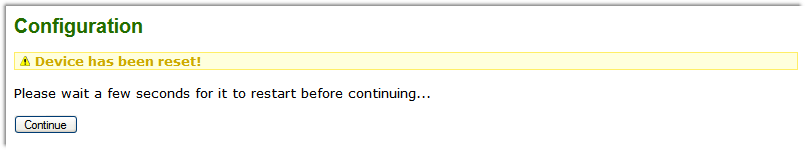

Remote restarting the device

You can perform a remote restart of the device from the web interface. A remote restart is similar to power cycling the device. Possibly connected clients are disconnected and communication is interrupted until the device has rebooted.

To perform a remote restart, click on the Configuration sub-menu and then

click on the Restart menu entry. This will open the device restart

page as shown below:

Click on the Restart button to perform a restart of the device. The

restart is confirmed with the following notification:

Please allow a few seconds before continuing working with the device as it has to fully start-up first, before being able to respond to further web browser requests.

|

|

After a remote restart a Watchdog reset alarm is shown on the device' home page. This is a side-effect of the remote restart procedure and the alarm shall be ignored and cleared. |

Modbus data reference

This chapter describes how GCP-30 and LS 4 data values are organized in logical blocks and accessed via Modbus.

The GCP-MG supports the Modbus function codes 03, 04, 06 and 16. A maximum of 100 16-bit words can be requested with Modbus command 04. This makes it possible to read the complete data set of a GCP-30 or LS 4 unit with a single Modbus transaction.

| Modbus function code | Function name | Access | Max. number of 16-bit words per transaction | Data table/block |

|---|---|---|---|---|

04 |

Read input registers |

read |

100 |

3:0000 |

03 |

Read holding registers |

write |

3 |

4:0000 |

06 |

Write single register |

write |

1 |

4:0000 |

16 |

Write multiple registers |

write |

3 |

4:0000 |

The GCP-MG emulates a virtual Modbus slave device for each GCP-30 and LS 4 unit connected to the CAN bus. This simplifies management of PLC and SCADA variable tag tables, as the Modbus start address is identical for all GCP-30 and LS 4 units.

The following tables show the relation of an individual unit with the Modbus slave ID and the Modbus register range:

| Unit | Modbus slave ID | Modbus read address range | Modbus write address range | Modbus floating point address range | CAN ID |

|---|---|---|---|---|---|

GCP-30 #1 |

1 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

801 |

GCP-30 #2 |

2 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

802 |

GCP-30 #3 |

3 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

803 |

GCP-30 #4 |

4 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

804 |

GCP-30 #5 |

5 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

805 |

GCP-30 #6 |

6 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

806 |

GCP-30 #7 |

7 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

807 |

GCP-30 #8 |

8 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

808 |

GCP-30 #9 |

9 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

809 |

GCP-30 #10 |

10 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

810 |

GCP-30 #11 |

11 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

811 |

GCP-30 #12 |

12 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

812 |

GCP-30 #13 |

13 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

813 |

GCP-30 #14 |

14 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

814 |

GCP-30 #15 |

15 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

815 |

GCP-30 #16 |

16 |

3:0001-3:0100 |

4:0001-4:0003 |

3:1001-3:1076 |

816 |

LS 4 #1 |

17 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

817 |

LS 4 #2 |

18 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

818 |

LS 4 #3 |

19 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

819 |

LS 4 #4 |

20 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

820 |

LS 4 #5 |

21 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

821 |

LS 4 #6 |

22 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

822 |

LS 4 #7 |

23 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

823 |

LS 4 #8 |

24 |

3:0001-3:0100 |

4:0003 |

3:1001-3:1034 |

824 |

A standard LS 4 occupies only the range from 3:0001 to 3:0029. The remaining range is reserved for future expansion of the LS 4 or custom versions.

|

|

If no response was obtained from the target GCP-30 unit, Modbus exception code 0B Gateway target device failed to respond is returned. |

The following table lists the Modbus exception responses sent by the gateway instead of a normal response message in case of an error:

| Modbus exception code | Exception name | Reason |

|---|---|---|

01 |

Illegal function |

A Modbus master sent a Modbus function which is not supported by the gateway. Please refer to the documentation of the individual data tables for valid function codes. |

02 |

Illegal data address |

A Modbus master queried a non-existing Modbus address or the queried range points outside of a data table. Please refer to the documentation of the individual data tables for valid address ranges. |

03 |

Illegal value |

A Modbus master sent a Modbus message which’s structure or implied length is invalid. Also returned if a Modbus master tries to access remote control functions for a unit configured as read-only. |

0B |

Gateway target device failed to respond |

A Modbus master tries to access data which is unavailable because no response was obtained from the target GCP-30 or LS 4 unit. Usually means that the unit is not present on the CAN bus. |

Since firmware version 1.3 the Input registers located in the 3:0001 and 3:1001 range can alternatively be accessed as Holding registers in the range 4:0101 and 4:1001 respectively.

GCP-30 MUX data table 3:0001

The GCP-30 MUX data table contains all data values a GCP-30 is transmitting cyclically on the CAN bus. A GCP-30 sends a value every 100 ms. Therefore it takes approximately between 2.3 and 3 seconds for a complete update of the data table with new values from the CAN bus. The data table can be polled much faster by a Modbus master, however faster poll rates would not offer higher update cycles.

The GCP-30 MUX data table is located in the so called Input register

address block, which sometimes is also identified with offset 3:0000.

[Alternative access as "Holding Registers" is possible at 4:0101 since firmware 1.3]

The block is accessed using Modbus function code 04 Read input registers.

Only Modbus address 0001 can be accessed at all times. All other Modbus addresses can only be accessed if the CAN communication between GCP-MG and GCP-30 has been established. If this is not the case, Modbus exception code 0B Gateway target device failed to respond is returned indicating the GCP-30 is not present on the CAN bus.

For the GCP-30 MUX data table, the GCP-MG acts as a transparent gateway between the GCP-30 unit and the Modbus. Except for the device status register at Modbus address 0001, it does not perform any modification to the representation of the data values.

The Woodward "GCP-30 Series Genset Control" manual [GCP30] is the ultimate reference for the encoding and representation of the data values. Please refer to the "Transmission Telegram" table in Appendix C "Interface Control" of this manual for further details.

The following table shows the relationship between Modbus addresses and the so called MUX identifiers or word numbers:

| Block | Modbus address | GCP-30 MUX | GCP-30 word no. | GCP-30 manual designator |

|---|---|---|---|---|

3 |

0001 |

n/a |

n/a |

CAN device status register |

3 |

0002 |

0/1 |

1 |

Generator voltage delta V12 |

3 |

0003 |

0/2 |

2 |

Generator frequency f |

3 |

0004 |

0/3 |

3 |

Actual generator real power P |

3 |

0005 |

1/1 |

4 |

Exponents |

3 |

0006 |

1/2 |

5 |

Real power set point value |

3 |

0007 |

1/3 |

6 |

Conversion factor steps to kW |

3 |

0008 |

2/1 |

7 |

Bus bar voltage delta V12 |

3 |

0009 |

2/2 |

8 |

Mains voltage delta V12 |

3 |

0010 |

2/3 |

9 |

Currently present alarm class |

3 |

0011 |

3/1 |

10 |

Control register 2 |

3 |

0012 |

3/2 |

11 |

Actual mains interchange (import/export) real power |

3 |

0013 |

3/3 |

12 |

Control register 1 |

3 |

0014 |

4/1 |

13 |

Alarm message IKD (SC06) |

3 |

0015 |

4/2 |

14 |

Internal alarm 6 |

3 |

0016 |

4/3 |

15 |

Generator voltage delta V23 |

3 |

0017 |

5/1 |

16 |

Generator voltage delta V31 |

3 |

0018 |

5/2 |

17 |

Generator voltage delta V1N |

3 |

0019 |

5/3 |

18 |

Generator voltage delta V2N |

3 |

0020 |

6/1 |

19 |

Generator voltage delta V3N |

3 |

0021 |

6/2 |

20 |

Configuration [T1]-[T4] |

3 |

0022 |

6/3 |

21 |

Engine speed measured via the Pickup |

3 |

0023 |

7/1 |

22 |

Generator current in L1 |

3 |

0024 |

7/2 |

23 |

Generator current in L2 |

3 |

0025 |

7/3 |

24 |

Generator current in L3 |

3 |

0026 |

8/1 |

25 |

Actual generator reactive power |

3 |

0027 |

8/2 |

26 |

Generator cos phi |

3 |

0028 |

8/3 |

27 |

Current reserve power in the system in kW |

3 |

0029 |

9/1 |

28 |

Current actual real power in the system |

3 |

0030 |

9/2 |

29 |

Number of participants on the CAN bus |

3 |

0031 |

9/3 |

30 |

High byte: Mains status, Low byte: Generator status |

3 |

0032 |

10/1 |

31 |

Exponents |

3 |

0033 |

10/2 |

32 |

Bus bar frequency |

3 |

0034 |

10/3 |

33 |

Configuration [T5]-[T8] |

3 |

0035 |

11/1 |

34 |

Mains voltage delta V23 |

3 |

0036 |

11/2 |

35 |

Mains voltage delta V31 |

3 |

0037 |

11/3 |

36 |

Mains voltage delta V1N |

3 |

0038 |

12/1 |

37 |

Mains voltage delta V2N |

3 |

0039 |

12/2 |

38 |

Mains voltage delta V3N |

3 |

0040 |

12/3 |

39 |

Mains frequency out off VN12/VN23/VN31 |

3 |

0041 |

13/1 |

40 |

Mains current in L1 |

3 |

0042 |

13/2 |

41 |

Mains reactive power |

3 |

0043 |

13/3 |

42 |

Mains power factor |

3 |

0044 |

14/1 |

43 |

Exponents |

3 |

0045 |

14/2 |

44 |

Exponents |

3 |

0046 |

14/3 |

45 |

Engine operating hours, high word |

3 |

0047 |

15/1 |

46 |

Engine operating hours, low word |

3 |

0048 |

15/2 |

47 |

Hours until next maintenance |

3 |

0049 |

15/3 |

48 |

Engine start number |

3 |

0050 |

16/1 |

49 |

Operation mode |

3 |

0051 |

16/2 |

50 |

Generator active energy, high word |

3 |

0052 |

16/3 |

51 |

Generator active energy, low word |

3 |

0053 |

17/1 |

52 |

Battery voltage |

3 |

0054 |

17/2 |

53 |

Internal alarm 1 |

3 |

0055 |

17/3 |

54 |

Internal alarm 2 |

3 |

0056 |

18/1 |

55 |

Internal alarm 3 |

3 |

0057 |

18/2 |

56 |

Internal alarm 4 |

3 |

0058 |

18/3 |

57 |

Internal alarm 5 |

3 |

0059 |

19/1 |

58 |

External alarm 1 |

3 |

0060 |

19/2 |

59 |

External alarm 2 |

3 |

0061 |

19/3 |

60 |

Internal alarm 7 |

3 |

0062 |

20/1 |

61 |

Analogue input T1 |

3 |

0063 |

20/2 |

62 |

Analogue input T2 |

3 |

0064 |

20/3 |

63 |

Analogue input T3 |

3 |

0065 |

21/1 |

64 |

Analogue input T4 |

3 |

0066 |

21/2 |

65 |

Analogue input T5 |

3 |

0067 |

21/3 |

66 |

Analogue input T6 |

3 |

0068 |

22/1 |

67 |

Analogue input T7 |

3 |

0069 |

22/2 |

68 |

Alarm messages IKD2 (SC06) |

3 |

0070 |

22/3 |

69 |

LCD-display / Pickup |

3 |

0071 - 0100 |

Not used by a standard GCP-30, reserved for options, future expansion or custom versions. See below for allocation by option SB03 and SC06. |

|

|

If no response was obtained from the target GCP-30 unit, Modbus exception code 0B Gateway target device failed to respond is returned. |

Allocation with options SB03 and SC06

| Block | Modbus address | GCP-30 MUX | GCP-30 word no. | SB03 option Cat CCM designator | SC06 option MTU MDEC designator |

|---|---|---|---|---|---|

3 |

0071 |

23/1 |

70 |

Coolant temperature |

Woodward ST-3 control lambda setpoint |

3 |

0072 |

23/2 |

71 |

Oil pressure |

Woodward ST-3 control lambda reading |

3 |

0073 |

23/3 |

72 |

Raw water temperature |

Woodward ST-3 control actuator position |

3 |

0074 |

24/1 |

73 |

Turbo charger intake temperature |

Engine speed |

3 |

0075 |

24/2 |

74 |

Oil temperature |

Oil pressure |

3 |

0076 |

24/3 |

75 |

Intake manifold temperature |

Alarm code |

3 |

0077 |

25/1 |

76 |

Throttle position |

Operating hours |

3 |

0078 |

25/2 |

77 |

Engine speed |

Coolant temperature |

3 |

0079 |

25/3 |

78 |

Multiplexed ECU alarms 1 |

Oil temperature |

3 |

0080 |

26/1 |

79 |

Multiplexed ECU alarms 2 |

Fuel temperature |

3 |

0081 |

26/2 |

80 |

Multiplexed ECU alarms 3 |

Speed reply |

3 |

0082 |

26/3 |

81 |

Multiplexed ECU alarms 4 |

Multiplexed ECU alarm group 1 |

3 |

0083 |

27/1 |

82 |

Multiplexed ECU alarm group 2 |

|

3 |

0084 |

27/2 |

83 |

Reserved MDEC bit 11 |

|

3 |

0085 |

27/3 |

84 |

Reserved MDEC bit 12 |

|

3 |

0086 |

28/1 |

85 |

Reserved MDEC bit 13 |

|

3 |

0087 |

28/2 |

86 |

Reserved MDEC bit 14 |

|

3 |

0088 |

28/3 |

87 |

Reserved MDEC bit 15 |

|

3 |

0089 |

29/1 |

88 |

Reserved MDEC bit 16 |

|

3 |

0090 |

29/2 |

89 |

Reserved MDEC bit 17 |

|

3 |

0091 |

29/3 |

90 |

Reserved MDEC bit 18 |

GCP-30 floating point table 3:1001

The GCP-30 floating point data table is located in the so called Input

register address block, which is sometimes also identified with offset

3:0000.

[Alternative access as Holding Registers is possible at 4:1001 since firmware 1.3]

This block is accessed using Modbus function code 04 Read input

registers.

The floating point values are encoded in industry standard single-precision (32-bit) IEEE 754 format. The 32-bit floating point values are transmitted as pairs of two consecutive 16-bit registers in little-endian word order.

| Block | Modbus address | GCP-30 MUX | GCP-30 word no. | GCP-30 manual designator | Unit |

|---|---|---|---|---|---|

3 |

1001 |

0/1 |

1 |

Generator voltage delta V12 |

V |

3 |

1003 |

0/2 |

2 |

Generator frequency f |

Hz |

3 |

1005 |

0/3 |

3 |

Actual generator real power P |

kW |

3 |

1007 |

1/2 |

5 |

Real power set point value |

kW |

3 |

1009 |

2/1 |

7 |

Busbar voltage delta V12 |

V |

3 |

1011 |

2/2 |

8 |

Mains voltage delta V12 |

V |

3 |

1013 |

3/2 |

11 |

Actual mains interchange (import/export) real power |

kW |

3 |

1015 |

4/3 |

15 |

Generator voltage delta V23 |

V |

3 |

1017 |

5/1 |

16 |

Generator voltage delta V31 |

V |

3 |

1019 |

5/2 |

17 |

Generator voltage delta V1N |

V |

3 |

1021 |

5/3 |

18 |

Generator voltage delta V2N |

V |

3 |

1023 |

6/1 |

19 |

Generator voltage delta V3N |

V |

3 |

1025 |

6/3 |

21 |

Engine speed measured via the pickup |

rpm |

3 |

1027 |

7/1 |

22 |

Generator current in L1 |

A |

3 |

1029 |

7/2 |

23 |

Generator current in L2 |

A |

3 |

1031 |

7/3 |

24 |

Generator current in L3 |

A |

3 |

1033 |

8/1 |

25 |

Actual generator reactive power |

kW |

3 |

1035 |

8/2 |

26 |

Generator cos phi |

|

3 |

1037 |

8/3 |

27 |

Current reserve power in the system in kW |

kW |

3 |

1039 |

9/1 |

28 |

Current actual real power in the system |

kW |

3 |

1041 |

10/2 |

32 |

Busbar frequency |

Hz |

3 |

1043 |

11/1 |

34 |

Mains voltage delta V23 |

V |

3 |

1045 |

11/2 |

35 |

Mains voltage delta V31 |

V |

3 |

1047 |

11/3 |

36 |

Mains voltage delta V1N |

V |

3 |

1049 |

12/1 |

37 |

Mains voltage delta V2N |

V |

3 |

1051 |

12/2 |

38 |

Mains voltage delta V3N |

V |

3 |

1053 |

12/3 |

39 |

Mains frequency out off VN12/VN23/VN31 |

V |

3 |

1055 |

13/1 |

40 |

Mains current in L1 |

A |

3 |

1057 |

13/2 |

41 |

Mains reactive power |

kVAR |

3 |

1059 |

13/3 |

42 |

Mains power factor |

|

3 |

1061 |

17/1 |

52 |

Battery voltage |

V |

3 |

1063 |

20/1 |

61 |

Analogue input T1 |

|

3 |

1065 |

20/2 |

62 |

Analogue input T2 |

|

3 |

1067 |

20/3 |

63 |

Analogue input T3 |

|

3 |

1069 |

21/1 |

64 |

Analogue input T4 |

|

3 |

1071 |

21/2 |

65 |

Analogue input T5 |

|

3 |

1073 |

21/3 |

66 |

Analogue input T6 |

|

3 |

1075 |

22/1 |

67 |

Analogue input T7 |

GCP-30 remote control data table 4:0001

The GCP-30 remote control data table is located in the so called Holding Register address block, which sometimes is also identified with offset 4:0000. This block can be written to using Modbus function code 16 Write multiple registers or function code 06 Write single register.

If remote control is enabled, the three remote control words are sent cyclically to the respective GCP-30. They are also stored in the GCP-MG's memory and can be read back using Modbus function code 03 Read holding registers.

|

|

Remote control is disabled by default and Modbus exception code 03 Illegal value is returned if a Modbus master tries to access remote control functions for a unit configured as read-only. Remote control can be enabled on a per unit basis through the GCP-30 settings page of the GCP-MG (see [ConfigModbusAccess]). |

| Block | Modbus address | GCP-30 word no. | GCP-30 manual designator | Encoding |

|---|---|---|---|---|

4 |

0001 |

501 |

Generator real power set-point |

kW with control argument |

4 |

0002 |

502 |

Generator power factor set-point |

cos phi x 100 |

4 |

0003 |

503 |

Control word |

Bit 1: 1 = Remote start |

|

|

If no response was obtained from the target GCP-30 unit, Modbus exception code 0B Gateway target device failed to respond is returned. |

LS 4 MUX data table 3:0001

The LS 4 MUX data table contains all data values a LS 4 is transmitting cyclically on the CAN bus. A LS 4 sends a value every 200 ms. Therefore it takes approximately 10 seconds for a complete update of the data table with new values from the CAN bus. The data table can be polled much faster by a Modbus master, however faster poll rates would not offer higher update cycles.

The LS 4 MUX data table is located in the so called Input register address

block, which sometimes is also identified with offset 3:0000.

[Alternative access as Holding Registers is possible at 4:0101 since firmware 1.3]

The block is accessed using Modbus function code 04 Read input registers.

Only Modbus address 0001 can be accessed at all times. All other Modbus addresses can only be accessed if the CAN communication between GCP-MG and LS 4 has been established. If this is not the case, a Modbus exception code 0B Gateway target device failed to respond is returned, indicating the LS 4 unit is not present on the CAN bus.

For the LS 4 MUX data table, the GCP-MG acts as a transparent gateway between the LS 4 unit and the Modbus. Except for the device status register at Modbus address 0001, it does not perform any modification to the representation of the data values.

The Woodward "LS 4 Circuit Breaker Controls" manual [LS4] is the ultimate reference for the encoding and representation of the data values. Please refer to the "Transmission telegram" table in Appendix E "Interface" of this manual for further details.

The following table shows the relationship between Modbus addresses and the so called MUX identifiers or word numbers.

| Block | Modbus address | LS 4 MUX | LS 4 word no. | LS 4 manual designator |

|---|---|---|---|---|

3 |

0001 |

n/a |

n/a |

CAN device status register |

3 |

0002 |

0/1 |

1 |

Protocol number 1600 |

3 |

0003 |

0/2 |

2 |

Voltage L12 system A |

3 |

0004 |

0/3 |

3 |

Voltage L23 system A |

3 |

0005 |

1/1 |

4 |

Voltage L31 system A |

3 |

0006 |

1/2 |

5 |

Voltage L1N system A |

3 |

0007 |

1/3 |

6 |

Voltage L2N system A |

3 |

0008 |

2/1 |

7 |

Voltage L3N system A |

3 |

0009 |

2/2 |

8 |

Frequency system A |

3 |

0010 |

2/3 |

9 |

Current L1 system A |

3 |

0011 |

3/1 |

10 |

Current L2 system A |

3 |

0012 |

3/2 |

11 |

Current L3 system A |

3 |

0013 |

3/3 |

12 |

Power factor |

3 |

0014 |

4/1 |

13 |

Real power system A |

3 |

0015 |

4/2 |

14 |

Reactive power system A |

3 |

0016 |

4/3 |

15 |

Voltage L12 system B |

3 |

0017 |

5/1 |

16 |

Voltage L23 system B |

3 |

0018 |

5/2 |

17 |

Voltage L31 system B |

3 |

0019 |

5/3 |

18 |

Frequency system B |

3 |

0020 |

6/1 |

19 |

Exponent |

3 |

0021 |

6/2 |

20 |

Exponent |

3 |

0022 |

6/3 |

21 |

Internal alarms 1 |

3 |

0023 |

7/1 |

22 |

Internal alarms 2 |

3 |

0024 |

7/2 |

23 |

Internal alarms 3 |

3 |

0025 |

7/3 |

24 |

Internal alarms 4 |

3 |

0026 |

8/1 |

25 |

Internal alarms 5 |

3 |

0027 |

8/2 |

26 |

Internal alarms 6 |

3 |

0028 |

8/3 |

27 |

Internal alarms 7 |

3 |

0029 |

9/1 |

28 |

Internal Diagnosis |

3 |

0030 - 0100 |

Not used by a standard LS 4, reserved for future expansion or custom versions. |

|

|

If no response was obtained from the target LS 4 unit, Modbus exception code 0B Gateway target device failed to respond is returned. |

LS 4 floating point data table 3:1001

The LS 4 floating point data table is located in the so called Input

register address block, which is sometimes also identified with offset

3:0000.

[Alternative access as Holding Registers is possible at 4:1001 since firmware 1.3]

This block is accessed using Modbus Function Code 04 Read input

registers.

The floating point values are encoded in industry standard single-precision (32-bit) IEEE 754 format. The 32-bit floating point values are transmitted as pairs of two consecutive 16-bit registers in little-endian word order.

| Block | Modbus address | LS 4 MUX | LS 4 word no. | LS 4 manual designator | Unit |

|---|---|---|---|---|---|

3 |

1001 |

0/2 |

2 |

Voltage L12 system A |

V |

3 |

1003 |

0/3 |

3 |

Voltage L23 system A |

V |

3 |

1005 |

1/1 |

4 |

Voltage L31 system A |

V |

3 |

1007 |

1/2 |

5 |

Voltage L1N system A |

V |

3 |

1009 |

1/3 |

6 |

Voltage L2N system A |

V |

3 |

1011 |

2/1 |

7 |

Voltage L3N system A |

V |

3 |

1013 |

2/2 |

8 |

Frequency system A |

Hz |

3 |

1015 |

2/3 |

9 |

Current L1 system A |

A |

3 |

1017 |

3/1 |

10 |

Current L2 system A |

A |

3 |

1019 |

3/2 |

11 |

Current L3 system A |

A |

3 |

1021 |

3/3 |

12 |

Power factor |

|

3 |

1023 |

4/1 |

13 |

Real power system A |

kW |

3 |

1025 |

4/2 |

14 |

Reactive power system A |

kVAR |

3 |

1027 |

4/3 |

15 |

Voltage L12 system B |

V |

3 |

1029 |

5/1 |

16 |

Voltage L23 system B |

V |

3 |

1031 |

5/2 |

17 |

Voltage L31 system B |

V |

3 |

1033 |

5/3 |

18 |

Frequency system B |

Hz |

|

|

If no response was obtained from the target LS 4 unit, Modbus exception code 0B Gateway target device failed to respond is returned. |

LS 4 remote control data table 4:0001

The LS 4 remote control data table is located in the so called Holding Register address block, which sometimes is also identified with offset 4:0000. The block can be written to using Modbus function code 16 Write multiple registers or function code 06 Write single register.

If Remote Control is enabled, the three remote control words are sent cyclically to the respective LS 4. They are also stored in the GCP-MG's memory and can be read back using Modbus function code 03 Read holding registers.

|

|

Remote control is disabled by default and Modbus exception code 03 Illegal value is returned if a Modbus master tries to access remote control functions for a unit configured as read-only |

Remote control can be enabled on a per unit basis through the LS 4 settings page of the GCP-MG (see [ConfigModbusAccess]).

| Block | Modbus address | LS 4 word no. | LS 4 manual designator | Encoding |

|---|---|---|---|---|

4 |

0001 |

501 |

(not used for LS 4) |

|

4 |

0002 |

502 |

(not used for LS 4) |

|

4 |

0003 |

503 |

Control word |

Bit 1: 1 = Open CB (high priority) |

|

|

If no response was obtained from the target LS 4 unit, Modbus exception code 0B Gateway target device failed to respond is returned. |

Decommissioning

Before disconnecting the GCP-MG unit please follow the rules in [Safety].

Disconnecting

|

|

|

Disposal

|

|

This product must be disposed of at a specialized electronic waste recycling facility. Do not dispose of in domestic waste. |

Appendix A: Specifications

|

Product name

|

GCP-MG |

Interfaces |

|

Ethernet |

1 |

Serial ports |

1 for Modbus (either RS-232 or RS-485, software configurable) |

CAN |

1 |

User interface |

|

LED indicators |

Power (green), Ethernet link (green), 2 status (bi-color red/green) |

Monitoring & configuration |

Web browser based |

Diagnostic |

|

High availability features |

Watchdog supervision, brown-out detection |

CAN interface |

|

Connector |

male 9-pin D-sub, CiA DS-102 pin-out |

Physical layer |

ISO 11898 |

Isolation |

non-isolated |

Speed |

125 kBit/s |

Max. number of connected nodes |

64 |

Protocols |

CAL 2.0 |

RS-485 Modbus interface |

|

Connector |

3.81 mm 6-pin pluggable terminal block header |

Physical layer |

EIA-485-A, 2-wire |

Isolation |

non-isolated |

Speed |

300, 600, 1200, 2400, 4800, 9600, 19200, 57600, 115200 bps |

Max. number of nodes |

32 |

Protocols |

Modbus RTU slave |

RS-232 Modbus interface |

|

Connector |

male 9-pin D-sub, DTE, EIA-574 pin-out |

Physical layer |

EIA-232-F |

Isolation |

non-isolated |

Signals |

RXD, TXD, RTS, CTS, DTR, DSR, DCD, RI |

Speed |

300, 600, 1200, 2400, 4800, 9600, 19200, 57600, 115200 bps |

Protocols |

Modbus RTU slave |

RS-232 diagnostic port |

|

Connector |

male 9-pin D-sub, DTE, EIA-574 pin-out |

Physical layer |

EIA-232-F |

Isolation |

n/a |

Signals |

RXD, TXD |

Speed |

9600 bps |

Protocols |

ASCII terminal |

Ethernet port |

|

Connector |

8-pin RJ-45 socket for Cat 5 UTP |

Physical & Data Link Layer Layer |

IEEE 802.3i 10BASE-T |

Isolation |

1.5 kV galvanic |

Speed |

10 Mbit/s |

Max. cable length |

100 m (328 ft) |

Ethernet frame types |

802.3 |

Protocols |

Modbus/TCP slave, HTTP, IP, TCP, ARP |

Concurrent connections |

2 Modbus/TCP, 2 HTTP |

Power supply |

|

Connector |

3.81 mm 2-pin pluggable terminal block header |

Voltage |

10-30 V DC |

Current |

30 mA typical @ 24 V DC |

Intrinsic consumption |

750 mW |

Electromagnetic compatibility |

|

Emissions (radiated and conducted) |

AS/NZS CISPR 22 / EN 55022 (Class A) |

Immunity |

EN 55024 |

Electrostatic discharge |

EN 61000-4-2 |

Radiated RF |

EN 61000-4-3 |

Fast transients |

EN 61000-4-4 |

Conducted RF |

EN 61000-4-6 |

Enclosure |

|

Material |

Self-extinguishing PC/ABS blend (UL 94-V0) |

Mounting |

35 mm DIN rail (EN 60715) |

Classification / Type rating |

IP 20 / NEMA Type 1 |

Cooling |

Convection |

Environmental |

|

Operating temperature |

0 to 60 °C / 32 to 140 °F |

Storage temperature |

-25 to 85 °C / -13 to 185 °F |

Humidity |

10 to 95% non condensing |

Operating ambience |

Free from corrosive gas, minimal dust |

Physical |

|

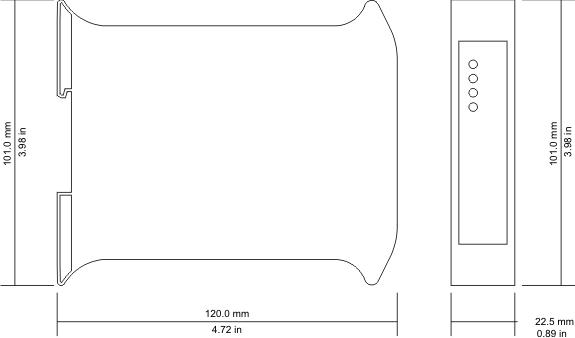

Dimensions |

101 x 22.5 x 120 mm / 3.98 x 0.886 x 4.72 in |

Weight |

0.13 kg / 0.287 lb |

Compliance |

|

Australia |

C-Tick |

Europe |

CE, RoHS |

USA |

FCC Part 15 (Class A) |

Canada |

ICES-003 (Class A) |

Dimensions

References

Glossary

- 10BASE-T

-

10 Mbit/s twisted pair Ethernet standard. Standardized in IEEE 802.3i

- APIPA

-

Automatic Private IP Addressing

- CAN

-

Controller area network. Standardized in ISO 11898.

- CiA DS-102

-

Standard for the pinout of CAN connectors

- Class A

-

Class A equipment is that used in commercial or light industrial environments.

- DCE

-

Data communications equipment. DTE and DCE devices have different pinouts for RS-232 connectors. A Modem for example is a DCE.

- DIN rail

-

35 mm wide mounting bracket standardized in DIN/EN 50022.

- DTE

-

Data terminal equipment. DTE and DCE devices have different pinouts for RS-232 connectors. A PC for example is a DTE.

- EIA-232

-

Standard for serial transmission of data between two devices, also known as RS-232 and V.24.

- EIA-422

-

ANSI/TIA/EIA-422 standard for serial transmission of data between two devices, also known as RS-422 and V.11.

- EIA-485

-

ANSI/TIA/EIA-485 standard for serial transmission of data between multiple devices, also known as RS-485.

- EIA-574

-

Standard for the pinout of serial D-sub connectors.

- EMC

-

Electromagnetic compatibility

- EMI

-

Electromagnetic interference

- ESD

-

Electrostatic discharge. ESD can damage electronic equipment.

- IEEE

-

Institute of Electrical and Electronics Engineers

- IP

-

Ingress Protection Rating standardized in IEC 60529. Standard for various grades of electrical enclosures.

- ISO

-

International Standards Organisation

- MAC address

-

Every piece of Ethernet hardware has a unique number assigned to it called it’s MAC address. MAC addresses are administered and assigned by the IEEE organization.

- Modbus

-

Fieldbus protocol used in the process automation industry. It uses a master and slave structure. Originally developed by Modicon, now part of Schneider Automation.

- NEMA

-

National Electrical Manufacturers Association. NEMA defines standards for various grades of electrical enclosures.

- Node

-

A communications device on the network

- PC/ABS

-

Polycarbonate-ABS. Widely used thermoplastic material.

- PLC

-

Programmable Logic Controller

- RS-232

-

See EIA-232.

- RS-422

-

See EIA-422.

- RS-485

-

See EIA-485.

- UL 94

-

Plastics flammability standard released by Underwriters Laboratories of the USA.

Document revision history

|

2007-05-14, 1.0

|

Initial Release for hardware version J367-S3-PB and firmware version 1.0 |

|

2008-07-28, 1.1

|

LED description added. Added max. number of Modbus/TCP connections. Corrected weight. Updated company name and address. Editorial Changes. |

|

2010-10-32, 1.2

|

Added alternative holding register address range. Editorial Changes. |

|

2011-04-06, 1.3

|

Editorial Changes. |

No part of this material may be reproduced or transmitted in any form or by any means or used to make any derivative work without express written consent from the copyright holders.

proconX is a trademark of proconX Pty Ltd. Modbus is a registered trademark of Schneider Automation Inc. All other product and brand names mentioned in this document may be trademarks or registered trademarks of their respective owners.

proconX Pty Ltd makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warranty which is detailed in the Terms and Conditions located on the Company’s Website. The Company assumes no responsibility for any errors which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without notice, and does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of proconX are granted by the Company in connection with the sale of proconX products, expressly or by implication. proconX products are not authorized for use as critical components in life support devices or systems.

We provide an electronic support and feedback system for our proconX products. It can be accessed through the following web link:

Your feedback and comments are always welcome. It helps improving this product.

For further information about the GCP-MG product or this document please contact us at:

proconX Pty Ltd Unit 7 / 14 Argon St Sumner QLD 4074 Australia Tel +61-7-3376 3911 Website: http://www.proconx.com/gcpmg